HRS Vortex Chassis Noise Reduction

- Price

- $1,630.00

This item qualifies for our new in-store fulfillment incentive program. Orders over $250 placed online and picked up in-store are now eligible for your choice of a complementary vinyl LP or Burmester Audio CD (up to a $40 retail value) upon pickup. We're excited to welcome you to our showroom!

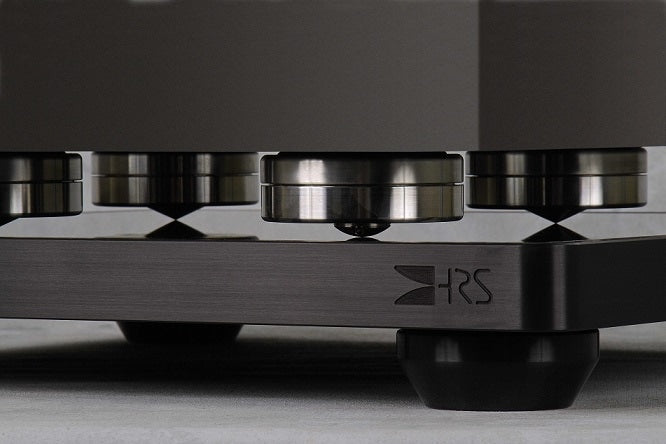

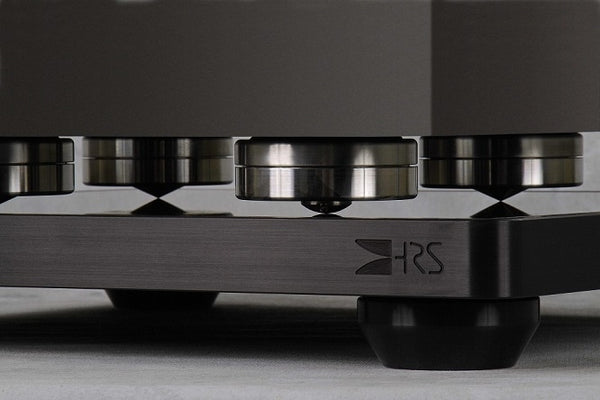

The Vortex is designed to be placed in direct contact with the chassis, not under existing component feet, with the point of the Vortex in contact with the HRS Isolation Base and the large diameter in direct contact with the component chassis.

OVERVIEW

The custom material interface used within the Vortex steel outer case is optimized to push the limits of resolution and dynamics without brightness, fatigue or high frequency noise. This material is developed by HRS specifically for the Vortex primary interface to get the best of all musical qualities combined from the compound.

The Vortex also contains a second custom internal element that dissipates the chassis energy as it passes through the Vortex’s non-magnetic stainless steel housing. The patent pending design of the Vortex housing passes the energy along a specific length path allowing the internal parasitic element time to deplete the energy and prevent it from returning to the system.

The Vortex is available in a fixed height as well as an adjustable height and has a non-magnetic stainless steel finish.

The Vortex is designed to be sold in sets of 4, which include 3 Fixed Height Vortex (V150) and 1 Adjustable Height Vortex (V150A).

FEATURES

- Can be used with any component weight.

- Gimbal system ensures intimate contact with chassis at every location.

- Fixed and adjustable Vortex models obtain maximum performance from small and large component chassis.

- Two different custom HRS materials for optimal performance of key interface with chassis and internal energy dissipation elements.

- High quality precision machined non-magnetic stainless steel outer housing.

- Performance optimized for use with all HRS Isolation Bases.

SPECIFICATIONS

Recommended use of Vortex based on component size:

Small Components (less than 100 square inches):

Three fixed Vortex (V150) are required to make the component stable. Do not use fewer than 3 fixed units.

3 Vortexes, all fixed

Normal Components (approximately 150 square inches and larger):

HRS strongly recommends using more than three units to obtain maximum performance. Each unit above a quantity of 3 must be the adjustable Vortex (V150A).

Four Vortexes (3 fixed, 1 adjustable)

Larger Components (approximately 300 square inches and larger):

Feel free to add additional adjustable Vortex (V150A) to system to properly reduce chassis noise. HRS recommends using up to 5 or more Vortex (Ex. 3 V150 plus 2 V150A) on larger components.

Five Vortexes (3 fixed, 2 adjustable)